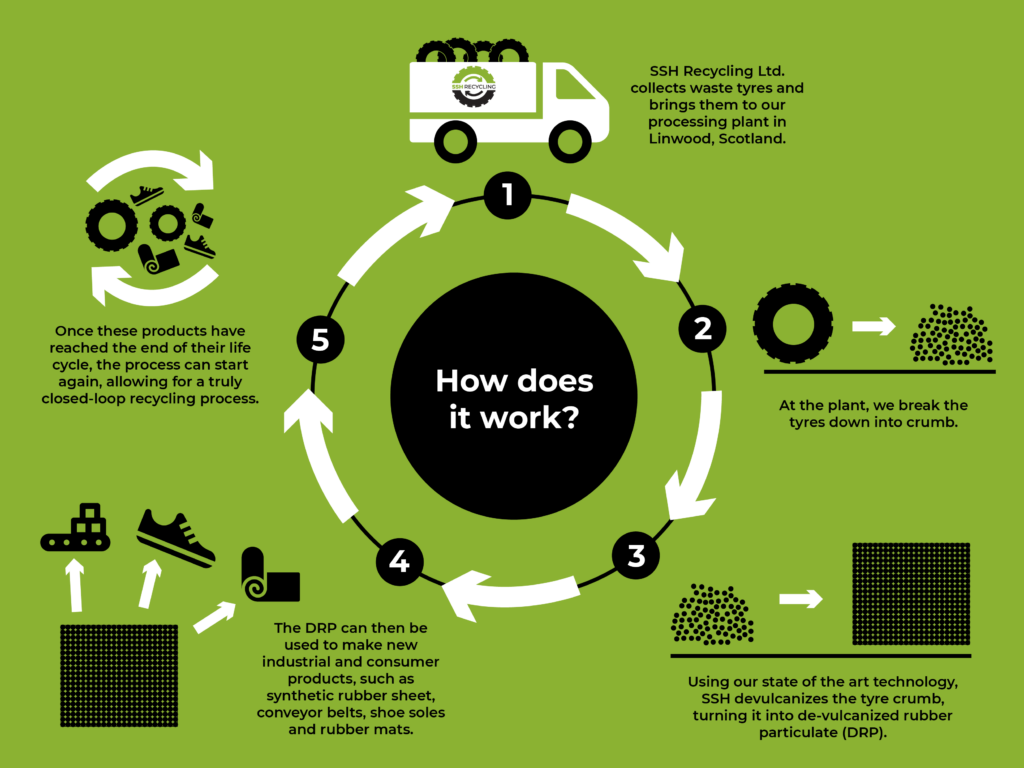

We’ve developed a pioneering approach to tyre recycling that’s reshaping the industry and setting new standards for sustainability in the UK. Our unique devulcanisation process makes us the first UK facility to vertically recycle tyres – turning waste products into virgin materials which can be recycled infinitely.

SSH Recycling isn’t just solving the UK’s waste tyre problem – we’re creating a blueprint for sustainable resource management. By combining innovation, efficiency, and a commitment to zero waste, we’re proving that tyres don’t have to end up in landfills or harm the environment.

Groundbreaking Technology

Unlike traditional methods that turn waste tyres into limited-use products like playground mats, we go further—producing high-quality materials that can be transported across borders and used in manufacturing.

This innovative, entirely mechanical process requires no chemical additives, ensuring a clean, sustainable approach with no waste byproducts.

Once operational, our facility will produce high-value materials that support a wide range of industries:

- Tyre-Derived Polymer (TDP): A sustainable alternative to virgin rubber, TDP can replace up to 90% of new rubber in tyre manufacturing, reducing environmental impact.

- Crumb Rubber: Used in tarmac, playground mats, and industrial materials, crumb rubber provides durable, eco-friendly solutions for construction and manufacturing.

- Metal and Fibre Aggregates: Metals extracted from tyres are repurposed in place of pig iron, while fibres find new life in textiles, carpets, and construction materials.